This project has received funding from the European Union's Horizon Europe research and innovation program under grant agreement No 101181056

About the

RETAIN Project

Project Approach

The RETAIN is a project funded by the European Commission under the Horizon Europe programme, aiming to demonstrate effective circular value chains for complex plastic materials. Specifically targeting PVC tarpaulins, durable and composite-like materials that are difficult to recycle, the project promotes innovation in collection, reuse, repair, remanufacturing, recycling, and ecodesign. RETAIN is driven by a strong international collaboration, bringing together 15 partners from 7 EU countries (Belgium, Netherlands, Germany, Austria, Spain, Italy, and the Czech Republic) to address the environmental and technical challenges associated with these widely used materials.

Key pillars of the RETAIN approach include:

).png)

Technology Development & Demonstration

– Further development and upscaling of mechanical, physical, and selective dissolution recycling technologies.

– Demonstration of these processes at TRL8 across three EU-based demo sites, processing both post-production and end-of-life tarpaulins.

)%20(2).png)

Digital Product Passport (DPP)

– Development of a robust Digital Product Passport system to enable traceability, support certification, and ensure data transparency for environmental and social impact assessments

)%20(1).png)

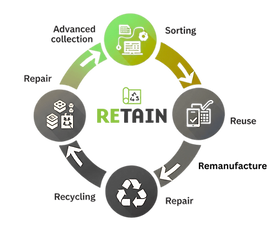

Circular Business Models

– Implementation of end-to-end circular practices including advanced collection, sorting, repair, reuse, remanufacturing, and recycling.

– Engagement of value chain actors in closed-loop systems to support the uptake of circular materials.

Lifecycle and Process Optimization

– Integration of an efficient decision-making mechanism (RETAIN gate control) to guide the most sustainable treatment paths for tarpaulins based on real-time material and lifecycle data.

Knowledge Sharing & Standardization

– Contribution to EU and international standards and alignment with existing circularity and recycling initiatives.

– Inclusion of training, education, and stakeholder engagement to ensure long-term scalability and knowledge transfer.

Impact-Driven Implementation

– Focused on achieving at least 90% circular use of tarpaulins by 2036 through combined environmental, economic, and social impact measurement and continuous improvement strategies.

Context

Tarpaulins are complex composite-like materials, typically composed of polyethylene terephthalate (PET) as reinforcement material and plasticized/soft polyvinyl chloride (PVC) as coating material. These durable plastics have a wide range of applications, going from trailer covers to professional tents and from advertisement banners to biogas membranes. Each year 200 kton of tarpaulins enter the EU market, 65% of this volume, corresponding to ca. 200 Mio m2, being produced in the EU. After their functional lifetime, which ranges from a few months up to 30 years, over 99% of tarpaulins currently end up as landfill or are being incinerated, as today’s recycling technologies are insufficient.

Further information and updates on the RETAIN project will be communicated soon through dedicated channels. Stay tuned for the latest developments and opportunities to engage.

Sustainable Solution

Circular Economy Approach

This approach ensures that RETAIN will not only provide technical solutions to the recycling challenges of complex plastic materials but will also establish the business, digital, and regulatory foundations needed to scale circular tarpaulin use across Europe.

Photo of the RETAIN project team gathered in Kortrijk, Belgium, on 19-20 May 2025 for the kick-off meeting.